The Tevo Tarantula Prusa i3 A 3D Printing Overview

The Tevo Tarantula Prusa i3 is a popular 3D printer known for its affordability and open-source design. It’s a great choice for beginners and hobbyists looking to get into 3D printing. The printer is based on the Prusa i3 design, which is known for its robust structure and ease of modification. The Tevo Tarantula offers a decent build volume, allowing for a variety of projects. While it’s a capable printer out of the box, the Tevo Tarantula can greatly benefit from a few key upgrades. These upgrades can significantly improve print quality, reliability, and overall user experience. This article will explore five essential upgrades that can truly elevate your Tevo Tarantula. These enhancements can help you achieve professional-looking prints and extend the life of your printer. By strategically upgrading your Tevo Tarantula, you’ll be able to achieve a more enjoyable and productive 3D printing experience.

Extruder Upgrades

The extruder is a vital component of your 3D printer, responsible for feeding the filament into the hotend. The stock extruder on the Tevo Tarantula is often made of plastic, which can wear out over time, especially when using abrasive filaments or printing at high speeds. Upgrading the extruder is a smart move to ensure consistent and reliable filament feeding. A better extruder provides a consistent flow of filament, which directly improves print quality. Also, some stock extruders struggle with flexible filaments. Upgrading your extruder will help with printing various types of materials. Choosing a new extruder should prioritize durability and strong gripping capabilities, ensuring a more efficient and reliable printing process.

Upgrading to a Metal Extruder

A highly recommended upgrade for the Tevo Tarantula is replacing the plastic extruder with a metal one. Metal extruders, made from materials like aluminum or stainless steel, offer increased durability and wear resistance compared to their plastic counterparts. They provide a more stable platform for the filament, which reduces the chances of slippage or grinding. When upgrading to a metal extruder, you’ll typically replace the entire extruder assembly, including the motor mount and idler arm. The metal construction can handle higher temperatures and pressures, making it suitable for printing a wider range of filaments, including those that require higher printing temperatures. The enhanced grip of a metal extruder ensures smoother filament feeding, which leads to better print quality and fewer printing errors. This upgrade is a worthwhile investment for consistent and reliable printing.

Benefits of Metal Extruders

Metal extruders offer several key benefits. They’re significantly more durable and have a longer lifespan due to their robust metal construction. They also provide a much-improved grip on the filament, reducing slippage and grinding, which ensures a more consistent filament flow. Metal extruders can also handle higher printing temperatures. This expands the range of filaments you can print with, allowing for more experimentation with different materials. Furthermore, metal extruders often provide a more precise filament feeding mechanism, which enhances print quality by minimizing imperfections. Investing in a metal extruder can greatly enhance the overall reliability of your 3D printer and result in more successful prints, saving you time and material.

Upgrading the Hotend

The hotend is where the magic happens - where the filament is melted and extruded onto the print bed. Upgrading your hotend can significantly impact print quality and the range of materials you can use. Upgrading the hotend may involve replacing the heater block, nozzle, and heat break. Consider upgrading to a hotend that offers better temperature control, reduces the chance of clogs, and supports a wider range of filament types. The improved thermal management of a better hotend can result in more consistent melting and extrusion, leading to smoother, more detailed prints. The ability to reach higher temperatures can unlock the ability to print with materials like nylon or polycarbonate. This upgrade opens up new possibilities for your 3D printing projects.

Hotend Temperature Considerations

Accurate temperature control is vital for producing high-quality prints. Incorrect temperatures can lead to issues like under-extrusion, stringing, or warping. When upgrading your hotend, make sure it has precise temperature control and a reliable thermistor. Understanding the correct printing temperatures for different filaments is essential for making the most of your hotend upgrade. Proper temperature settings will improve layer adhesion, surface finish, and overall print quality. Always refer to the filament manufacturer’s recommendations for the best results. Properly calibrating the hotend temperature is key to achieving the best prints.

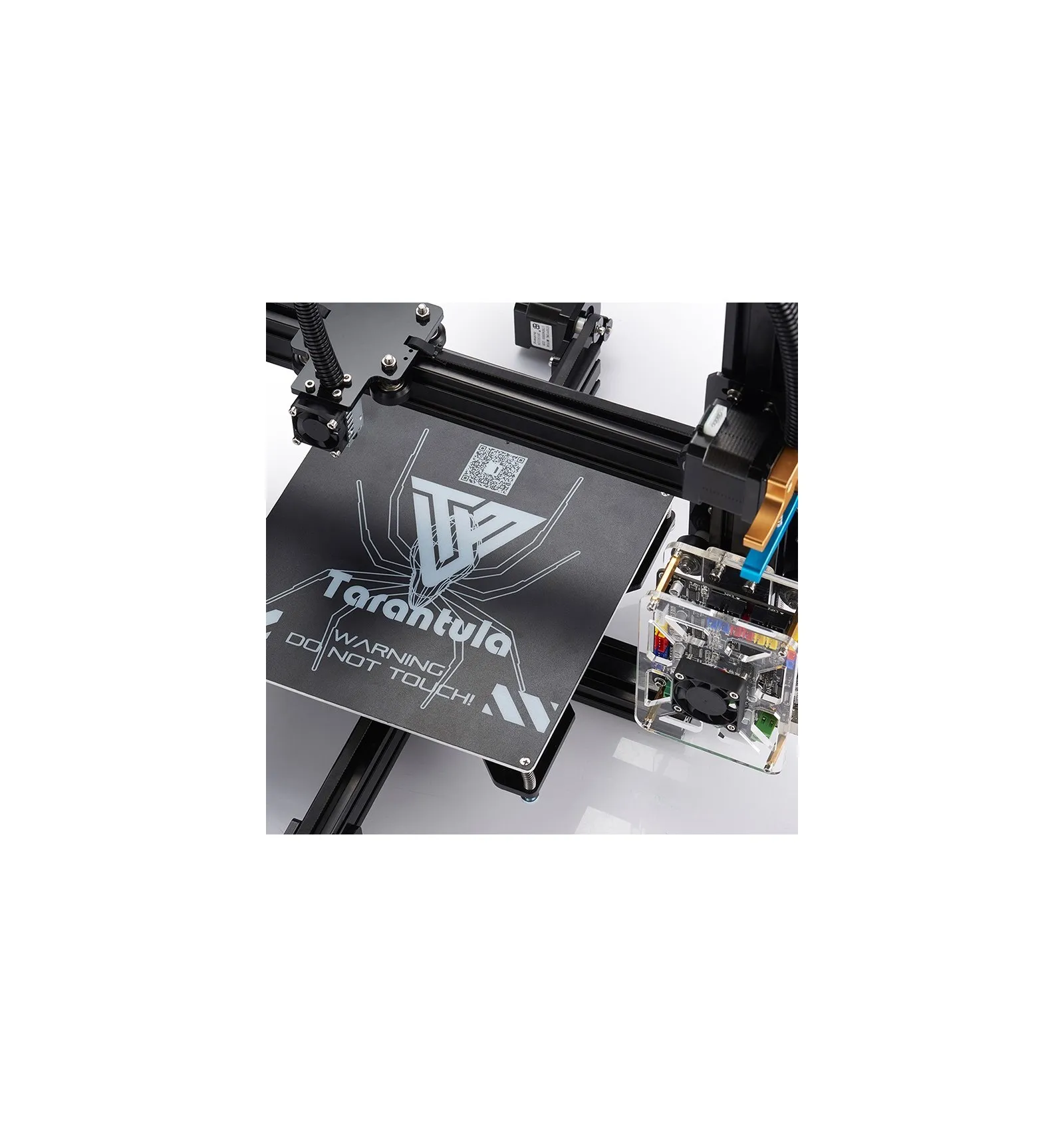

Bed and Leveling Upgrades

A level print bed is crucial for successful 3D printing. An unleveled bed can lead to adhesion problems, warping, and other print defects. The Tevo Tarantula’s stock bed leveling system is often manual, which can be time-consuming and require frequent adjustments. Upgrading the bed and leveling system is a worthwhile investment. This often includes installing an automatic bed leveling (ABL) sensor and potentially replacing the print bed surface for improved adhesion. The right upgrades can automate the leveling process and enhance the print bed’s adhesion capabilities, leading to a more consistent and user-friendly printing experience. Proper bed leveling is a foundational element of 3D printing success.

Automatic Bed Leveling Systems

Automatic bed leveling (ABL) systems are a game-changer. These systems use a sensor to measure the distance between the nozzle and the print bed at multiple points, automatically adjusting the Z-axis height. This compensates for any variations in the bed’s surface. There are several types of ABL sensors, including inductive, capacitive, and BLTouch sensors. The benefits of ABL are simplified setup, fewer manual adjustments, and improved first-layer adhesion. With ABL, you can spend less time leveling the bed and more time printing. Proper calibration and firmware configuration are essential to ensure the ABL system works correctly. The investment in an ABL system will save time and reduce frustration.

Benefits of Auto-Leveling

The main benefit of automatic bed leveling is the time saved and improved print quality. ABL eliminates the need for manual bed leveling. It ensures the first layer adheres properly, reducing warping and defects. ABL systems also provide more consistent results across prints because the printer automatically adjusts for any bed variations. ABL gives you peace of mind, allowing you to start prints with confidence, knowing the bed is properly leveled. Choosing the correct ABL sensor is key. ABL provides many advantages, making it a highly recommended upgrade for the Tevo Tarantula.

Upgrading the Print Bed Surface

The print bed surface plays a crucial role in print adhesion. The stock surface may not always provide the best adhesion. Upgrading your print bed surface can greatly improve print quality and reduce failed prints. Popular choices include glass beds, PEI sheets, and magnetic build surfaces. Each offers different advantages. Glass beds provide a smooth surface and easy print removal. PEI sheets offer excellent adhesion and flexibility. Magnetic build surfaces offer a great balance of convenience and adhesion. Choosing the right bed surface depends on your printing needs. A reliable print bed surface is essential for a successful 3D printing experience. A good bed surface will reduce the chances of prints detaching during printing.

Firmware and Control Board

The firmware and control board are the brains of your 3D printer, managing its operations. The firmware controls the printer’s functions, while the control board processes all the commands. Upgrading these can significantly improve your printing experience. It can unlock advanced features, enhance print quality, and give you more control. Firmware upgrades involve updating the software to the latest version, while control board upgrades often involve replacing the existing board with a more powerful one. These upgrades can bring noticeable improvements to your Tevo Tarantula.

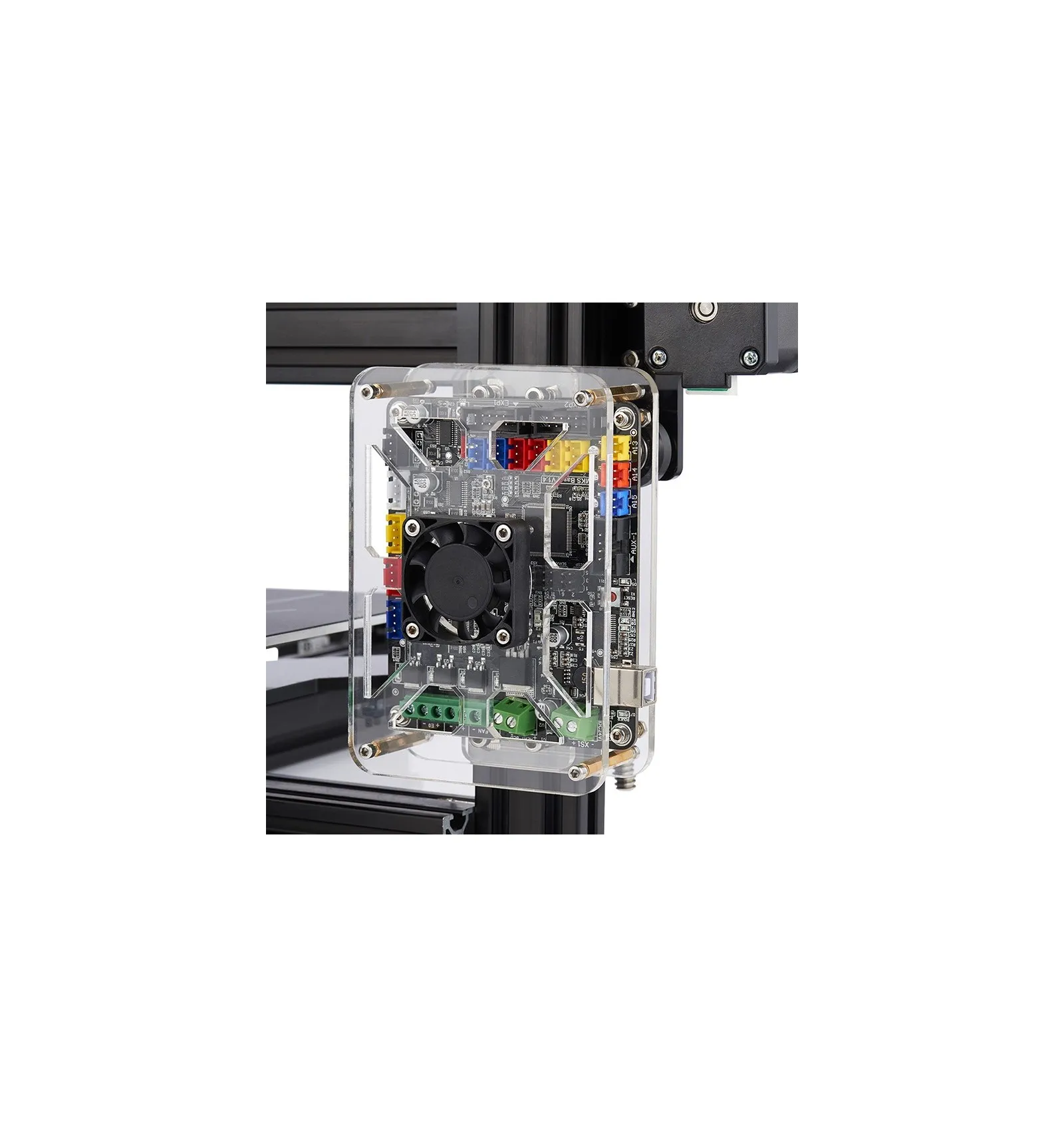

Upgrading the Control Board

Upgrading the control board can unlock numerous benefits, including improved processing power, increased memory, and support for advanced features. Many upgraded boards are compatible with firmware like Marlin, providing more control. A better control board can handle more complex print jobs and provide smoother and quieter operation. When selecting a control board, consider its compatibility with your printer’s components, as well as its support for features like ABL and Wi-Fi connectivity. Upgrading the control board is more involved than other upgrades, requiring some technical knowledge. The effort is worth it for the improved performance and control it provides. The right control board can help you achieve better results.

Benefits of an Upgraded Control Board

The benefits of an upgraded control board are significant. They include enhanced processing power, which leads to faster print speeds and improved quality. Increased memory allows for more complex models. Upgraded boards often support advanced features like sensorless homing and TMC stepper motor drivers, which can reduce noise and improve accuracy. These boards give you greater flexibility and customization options. A more capable control board can make your Tevo Tarantula more versatile and efficient, delivering higher performance and capabilities. An upgraded control board is an investment in your printer’s future.

Firmware Updates and Tuning

Firmware updates are essential for keeping your 3D printer running at its best. They can resolve bugs, improve performance, and introduce new features. Regularly updating your firmware is a straightforward process that can lead to significant improvements. Firmware tuning involves adjusting settings like acceleration, jerk, and steps per millimeter to optimize the printer’s performance. Many resources and online communities offer guidance and pre-configured settings for the Tevo Tarantula. Proper firmware tuning can significantly improve print quality, especially when paired with other upgrades. Staying up-to-date is crucial for maximizing your printer’s efficiency. Firmware updates are a key aspect of maintaining and improving your printer.

Enclosure for the Tevo Tarantula

Enclosing your Tevo Tarantula is advantageous, especially when printing materials that are sensitive to temperature changes or release fumes. An enclosure helps to maintain a stable printing environment, leading to improved print quality and reduced warping. The enclosure keeps out drafts and dust, enhancing safety. Building or buying an enclosure is a smart move if you plan to print with materials like ABS or nylon. The enclosure provides a more controlled environment for your prints. If you print with these materials, then an enclosure is a must-have.

Benefits of an Enclosure

The main benefits of enclosing a 3D printer are consistent print quality, reduced warping, and improved safety. A stable temperature environment is crucial for printing materials like ABS, which are prone to warping. Enclosures help maintain that environment. They reduce drafts and particles, improving print quality. They also contain fumes and odors, making your workspace safer. When considering an enclosure, think about its size, materials, and ventilation. A well-designed enclosure will significantly improve your 3D printing experience, especially if you use specific materials. An enclosure is a great investment.

Temperature and Filament Considerations

When using an enclosure, consider temperature and filament requirements. Different filaments require different printing temperatures, and an enclosure helps maintain these consistently. For example, ABS benefits from higher temperatures. When selecting an enclosure, consider the maximum temperature it can reach and if it has proper ventilation. Monitoring the temperature inside the enclosure is important. Understanding these aspects will help optimize your settings and get the best results. Proper temperature control is important to the success of your prints.

Conclusion

Upgrading your Tevo Tarantula is a great way to improve print quality, reliability, and performance. By focusing on key areas like the extruder, hotend, bed leveling, control board, and enclosures, you can transform your printer. The five upgrades discussed in this article offer significant benefits. Start with the upgrades that align with your needs and budget. Continue to refine your machine as your skills and projects evolve. With planning, you can unlock the full potential of your Tevo Tarantula and enjoy a more satisfying 3D printing experience. Making improvements will make you more successful.