Choosing the Right Upgrades for Tevo Tarantula i3

The Tevo Tarantula i3 is a popular 3D printer known for its affordability and ease of use. However, like any machine, it can be improved through strategic upgrades. Choosing the right upgrades can significantly enhance print quality, reliability, and overall user experience. This guide will explore the top 5 upgrades you can implement on your Tevo Tarantula i3 to take your 3D printing to the next level. We’ll delve into each upgrade, discussing the benefits and helping you make informed decisions about enhancing your 3D printing capabilities with your Tevo Tarantula i3. The aluminum frame of the Tevo Tarantula i3 provides a solid base, and these upgrades will build upon its strengths. Making the right improvements ensures your printer continues to deliver outstanding results for years to come.

Why Upgrade Your Tevo Tarantula i3?

Upgrading your Tevo Tarantula i3 is a fantastic way to get more out of your 3D printer. The stock configuration is a great starting point, but certain enhancements can dramatically improve its performance. Upgrades can boost print speed, reduce errors, and increase the range of materials you can use. By investing in upgrades, you’re not just improving the printer; you’re enhancing your ability to bring your ideas to life. The improvements you make can pay off over time with better prints and less wasted material. This is especially valuable for the aluminum frame versions, as these are designed for stability and can handle more advanced upgrades. This means you can continue to build and expand your capabilities.

Benefits of Upgrading

The benefits of upgrading are numerous. You’ll likely see improvements in print quality, with smoother surfaces and finer details. Upgraded components often lead to fewer failed prints and reduced maintenance. Enhanced reliability is another key advantage. Upgrades can also expand the types of materials you can print with, allowing you to explore new possibilities. The aluminum frame structure will ensure the upgrade maintains integrity, making upgrades even more effective. Furthermore, the upgraded printer will be more efficient and less likely to encounter unexpected problems. Ultimately, these benefits translate to a more enjoyable and productive 3D printing experience.

Top 5 Upgrades for Tevo Tarantula i3

Upgraded Extruder

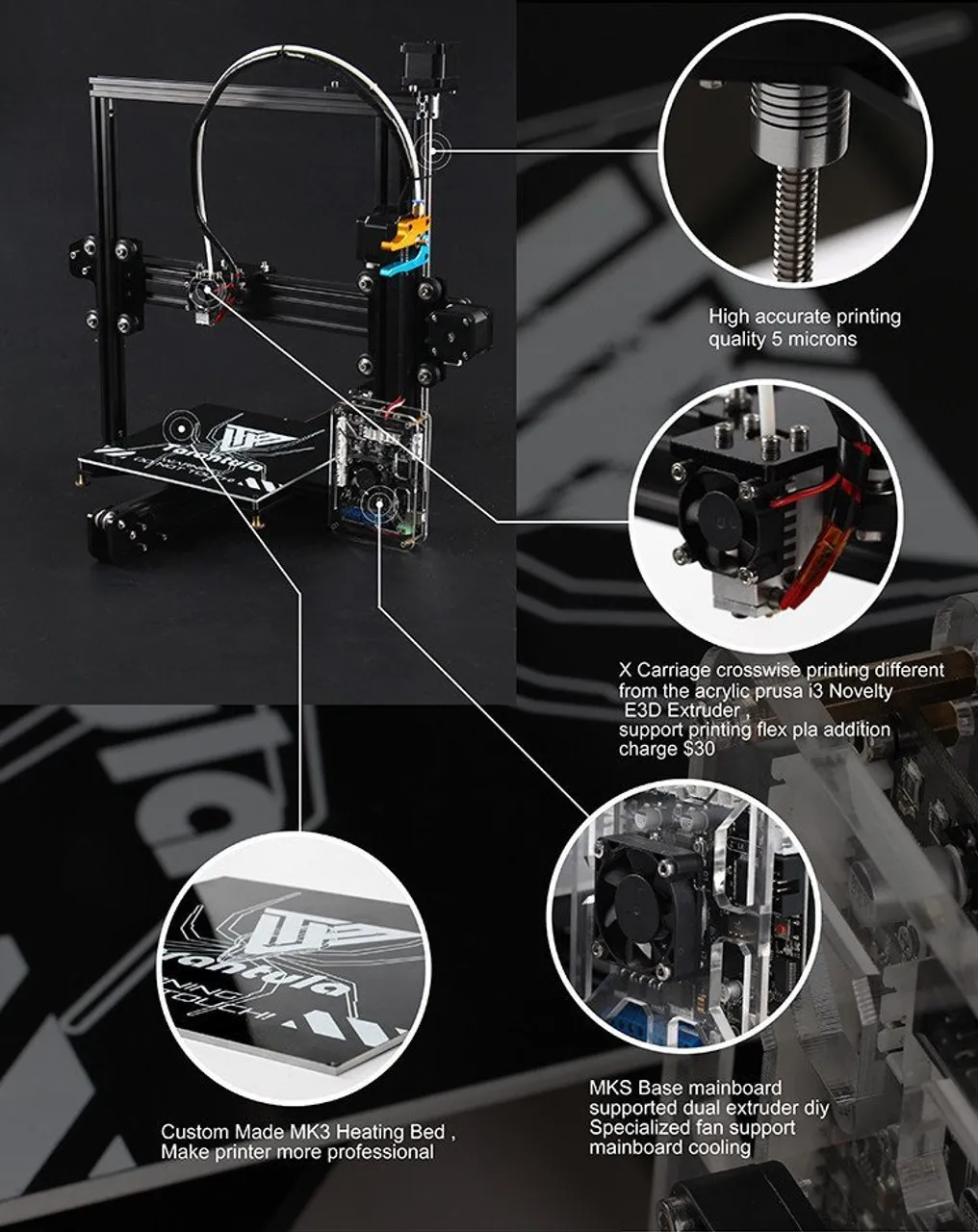

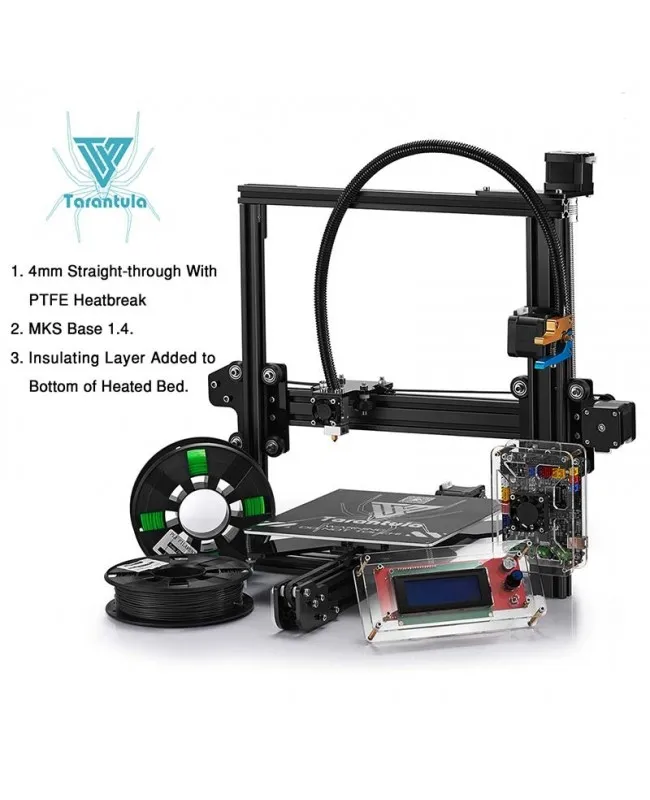

The extruder is a crucial component, responsible for pushing filament into the hotend. Upgrading to a better extruder can significantly improve print quality. Many users opt for all-metal extruders, which are more durable and can handle higher temperatures. A direct-drive extruder can also be a great choice, as it provides more precise filament control. Replacing the stock extruder with a more robust model reduces filament slippage and ensures a consistent flow, leading to better layer adhesion and overall print quality. Consider an extruder upgrade as one of the most impactful changes you can make to your Tevo Tarantula i3. Choose an upgrade that is reliable and easy to install, ensuring it will work well with your existing setup.

Advantages of a Better Extruder

A better extruder offers several key advantages. It increases the precision of filament feeding, leading to more consistent and accurate prints. Better filament control reduces the likelihood of under-extrusion or over-extrusion, both of which can ruin a print. Another benefit is the ability to print with a wider range of materials, including more challenging filaments like flexible TPU. A well-chosen extruder upgrade will improve overall print quality. It will also provide a more stable and reliable printing experience. The aluminum frame is sturdy enough to handle the upgrades without needing additional modifications.

Hotend Upgrade

The hotend is responsible for melting the filament. Upgrading the hotend can lead to faster printing speeds and improved temperature control. High-quality hotends, such as those from E3D, offer superior thermal performance and a more consistent melt. A new hotend can increase the maximum printing temperature, enabling you to print with a broader selection of filaments. Upgrading the hotend will also contribute to better overall print quality. This is especially beneficial for printing detailed models, as it can improve the accuracy of small features. The aluminum frame of the Tevo Tarantula i3 can easily accommodate these upgrades. The ease of installation makes this a worthwhile investment for any user.

Choosing a High-Quality Hotend

When selecting a hotend, consider factors such as temperature range, nozzle size, and compatibility. A higher temperature range will allow you to print with more advanced materials, while the nozzle size affects the level of detail and print speed. Ensure the new hotend is compatible with your printer’s existing components. Research different models and read reviews to make sure you are making an informed decision. A well-chosen hotend upgrade can significantly enhance the performance of your printer and provide a noticeable improvement. Be sure to select one that will easily install in your machine.

Upgrading the Bed Surface

The bed surface is where the first layer of your print adheres. An upgrade to the bed surface can improve adhesion and make removing prints easier. Popular options include glass beds, PEI sheets, and magnetic bed surfaces. These alternatives provide a flat, reliable surface. The best choice depends on your printing preferences and the materials you typically use. A better bed surface improves your printing experience, and ensures the finished result is more professional. Upgrading will guarantee fewer failed prints due to adhesion problems. It can also extend the life of your build surface.

Best Bed Surface Materials

Different bed surface materials offer unique benefits. Glass beds provide a smooth surface and excellent adhesion with the right settings. PEI sheets are known for their durability and good adhesion for various materials. Magnetic beds offer the convenience of easy print removal. Consider factors like ease of use, material compatibility, and the desired finish when making your choice. Experiment with different options to determine which best suits your printing needs. The correct bed surface will help you achieve better results with the aluminum frame. Make sure to calibrate your Z-offset after changing bed surfaces to ensure accurate first layers.

Control Board Upgrade

The control board is the brains of your 3D printer, and upgrading it can unlock new features and improve print quality. Consider upgrading to a board that supports features like silent stepper drivers, which reduce noise and improve print accuracy. Look for boards with more processing power and memory. This can provide faster print speeds and allow for more complex designs. Upgrading your control board will ensure the printer runs smoothly and without issue. Some options can include Wi-Fi connectivity and touch-screen interfaces. These improvements can make your 3D printing much easier. The aluminum frame provides the perfect base for these types of upgrades.

Advantages of Advanced Control Boards

Advanced control boards offer several benefits. They typically provide better print quality due to improved motion control and more precise temperature regulation. Silent stepper drivers reduce noise and improve overall print quality. Enhanced connectivity options make it easier to monitor and control your printer. Advanced control boards often support features like filament runout detection. These features can help prevent failed prints. The upgrade enhances the user experience, which makes the printing process easier. Look for a control board with good community support and documentation to simplify the upgrade process.

Enclosure for Your Tevo Tarantula i3

An enclosure can provide a controlled environment for your 3D prints. It helps maintain a consistent temperature, which improves print quality and reduces warping. An enclosure is especially beneficial when printing with materials that are sensitive to temperature fluctuations. An enclosure can also help contain fumes and reduce noise. You can construct an enclosure or purchase a pre-made one. Making an enclosure is a cost-effective option that allows you to customize it to your specific needs. It is a great addition and improves the print experience.

Why an Enclosure Matters

An enclosure provides a stable printing environment. It reduces warping, particularly when printing ABS or other materials that require a higher ambient temperature. It also helps to contain fumes and odors, making the 3D printing experience more pleasant. An enclosure helps prevent drafts and other environmental factors from affecting your prints. Moreover, it contributes to the safety of the printing process. Using an enclosure can improve print quality, reduce waste, and extend the life of your printer.

Conclusion Upgrading Tevo Tarantula i3

Upgrading your Tevo Tarantula i3 is an investment in your 3D printing journey. By upgrading key components like the extruder, hotend, bed surface, and control board, you can significantly improve print quality, reliability, and the range of materials you can use. Consider adding an enclosure to further enhance your printing experience. With these upgrades, your Tevo Tarantula i3 will deliver high-quality prints and provide years of enjoyment. Remember to research and choose upgrades that best suit your needs and printing preferences. The solid aluminum frame of the Tevo Tarantula i3 offers a strong base for all these modifications, helping ensure that you receive amazing results from all of your 3D printing projects. Happy printing!