Understanding the Importance of Tevo Tarantula Bed Leveling

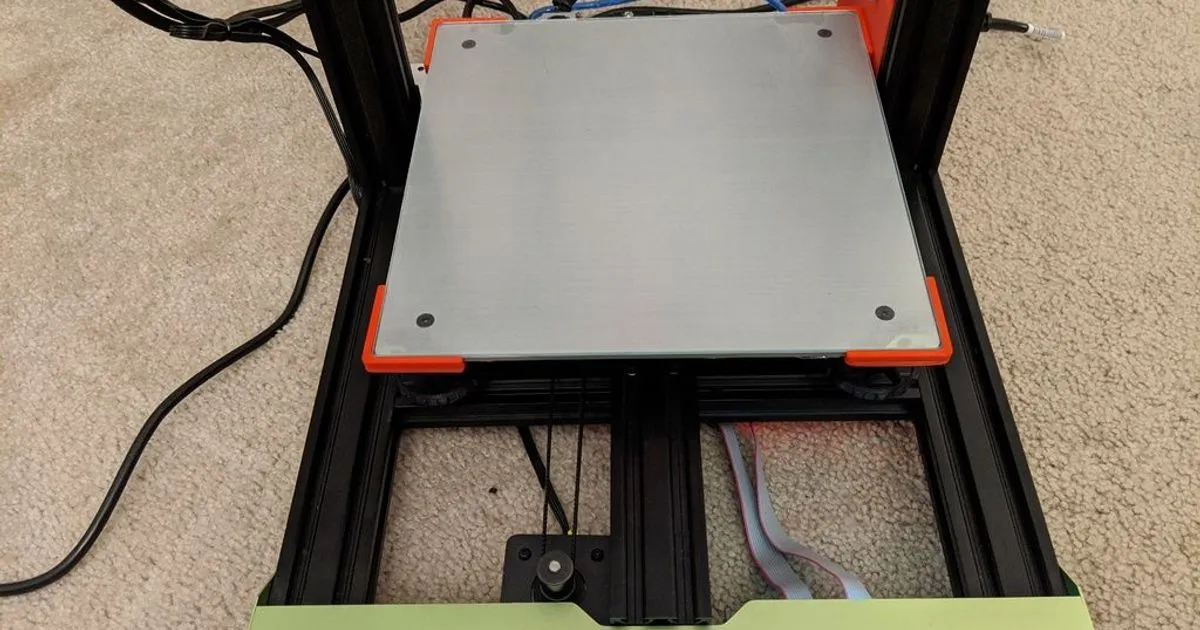

Bed leveling is paramount for successful 3D printing, and this is especially true for the Tevo Tarantula. Achieving a perfectly leveled bed ensures that the first layer of your print adheres correctly to the build surface. Without proper leveling, your prints are likely to fail, leading to wasted filament, time, and frustration. Understanding the fundamental importance of this process is the first step towards mastering your 3D printer. The Tevo Tarantula, like any 3D printer, demands precision in this area to create accurate and high-quality prints. Ignoring this crucial step can lead to a cascade of problems, from poor adhesion to warped prints.

Why Is Bed Leveling Crucial for 3D Printing

Bed leveling is crucial because it dictates the foundation upon which your 3D prints are built. A level bed ensures that the nozzle is the correct distance from the print surface across the entire printing area. This uniform distance is essential for proper filament extrusion and adhesion. If the bed is not level, the nozzle may be too close in some areas, causing the filament to be squished and potentially clogging the nozzle, or too far away in others, leading to poor adhesion and the print detaching from the bed. A level bed allows for consistent first-layer adhesion, which is a critical factor for the overall success of your print. Improper leveling is often the primary cause of print failures, highlighting its importance in the 3D printing process.

Common Problems Caused by Incorrect Leveling

Incorrect bed leveling on your Tevo Tarantula manifests in several common problems. One of the most frequent issues is poor first-layer adhesion. This leads to the print detaching from the bed mid-print, resulting in a failed print and wasted material. Another issue is elephant’s foot, where the base of the print is wider than the rest of the print, caused by the nozzle being too close to the bed. Warping is also a common problem; the corners of the print curl up due to uneven cooling and poor adhesion. Other problems include nozzle clogging, inconsistent layer lines, and generally poor print quality. These issues highlight the need for precision bed leveling to guarantee your prints come out as desired. The image of leveling-problems-3d-print.webp displays some of this common issues.

Top 5 Easy Tips for Tevo Tarantula Bed Leveling

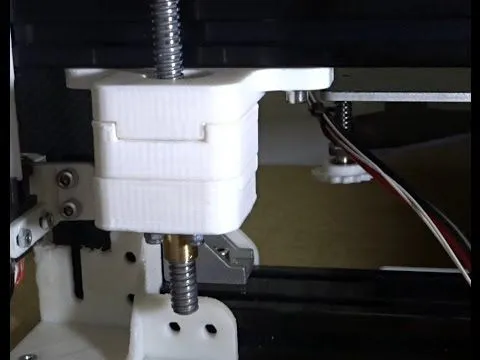

Tip 1 Adjust the Z-Axis Endstop

The Z-axis endstop determines the home position of your printer’s nozzle in the vertical (Z) direction. Adjusting this endstop correctly is the initial step for proper bed leveling. The endstop tells the printer when the nozzle is at its zero position, relative to the bed. If the endstop is not properly set, the nozzle may be too high or too low, which leads to the problems mentioned before. For the Tevo Tarantula, you can usually adjust the endstop by loosening the screw holding it in place and sliding it up or down. Be careful to not move the Z-axis limit switch too high, it can cause your nozzle to crash into the bed. Refer to the image adjust-z-axis-endstop.webp. The goal is to have the nozzle just above the bed surface when the printer homes.

How to Adjust the Z-Axis Endstop for Perfect Leveling

To adjust the Z-axis endstop, first, home your Tevo Tarantula. Then, manually move the nozzle to the center of the bed. Loosen the screw that secures the endstop. Place a piece of paper between the nozzle and the bed. Gently lower the bed or raise the nozzle until the nozzle lightly grips the paper; you should feel slight resistance when sliding the paper. Once you achieve this, tighten the endstop screw, ensuring the endstop is in contact. Fine-tune the adjustment by making small movements and retesting with the paper until you get the right amount of friction. This method establishes the correct Z-offset, crucial for perfect first-layer adhesion. Ensure that the endstop is secure and does not move when the printer is operating.

Tip 2 Use the Paper Test

The paper test is a simple yet effective method for leveling the bed on your Tevo Tarantula. After adjusting the Z-axis endstop, use a standard sheet of printer paper and slide it between the nozzle and the print bed. Move the nozzle to each of the four corners and the center of the bed. Adjust the bed leveling knobs at each corner until the paper lightly grips when you try to slide it. You should feel a slight resistance, but the paper should still move. If the paper is too loose, the nozzle is too far from the bed; if it’s too tight, the nozzle is too close. This test ensures a consistent distance between the nozzle and the bed across the entire printing surface. The image paper-test-3d-printer.webp exemplifies this process.

How to Perform the Paper Test

To perform the paper test, preheat your nozzle and bed to your printing temperatures. Home the printer and then manually move the nozzle to each corner of the bed. Place a piece of paper under the nozzle. Adjust the leveling knobs at each corner until you feel a slight resistance when sliding the paper. Repeat this process for the center of the bed. The goal is to achieve a consistent feel at all points on the bed. After leveling, the nozzle should be very close to the bed, just enough to slightly compress the first layer of filament. The paper test is an inexpensive and reliable way to ensure that the bed is properly leveled.

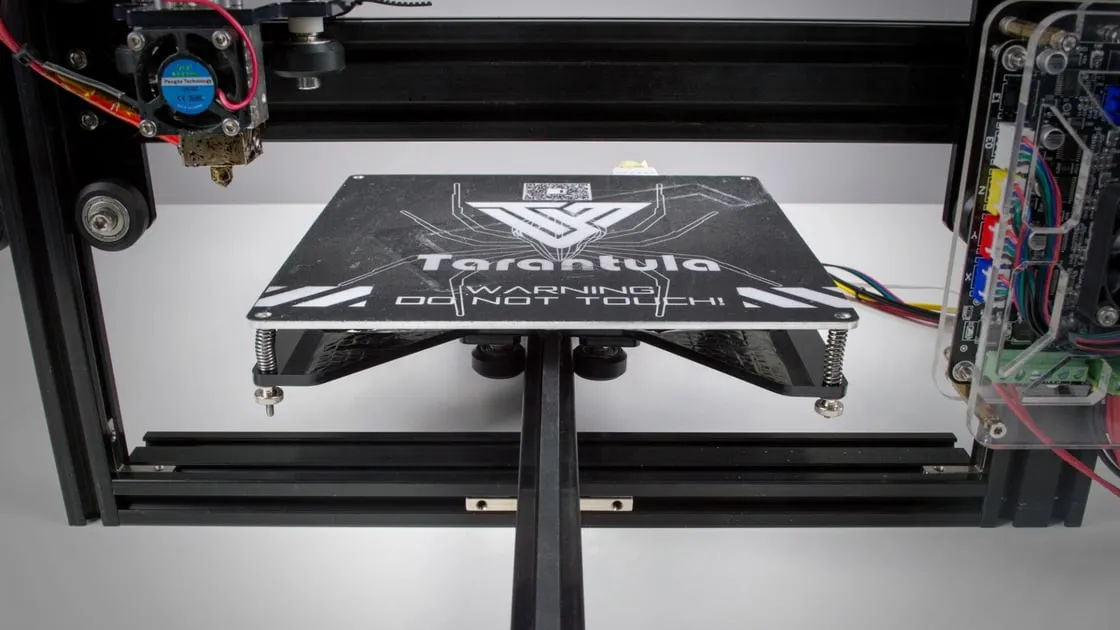

Tip 3 Level the Bed With Bed Leveling Knobs

The Tevo Tarantula uses bed leveling knobs located under the print bed. These knobs are the primary tool for adjusting the bed height. When performing the paper test, these knobs will be used to raise or lower the corners of the bed until the nozzle is the correct distance away. Turning a knob clockwise usually raises that corner of the bed, and counterclockwise lowers it. After the Z-axis endstop is set, you’ll utilize the knobs to fine-tune the bed level. Consistency is vital during the adjustments. The image bed-leveling-knobs.webp is a typical representation of the knobs you will interact with.

Best Practices for Using Bed Leveling Knobs

When using the leveling knobs, make small, incremental adjustments. Turn each knob only a fraction at a time and recheck the paper test after each adjustment. It’s best to go around the bed several times, making small adjustments at each corner until the paper test feels consistent at all points. Keep the bed clean to ensure the adjustments are accurate. The bed surface should be free of any debris or filament residue. If the bed has springs under it, make sure the springs are not excessively compressed or loose. Proper tension on the springs will contribute to a more stable and consistent leveling platform. The process requires patience and a careful approach to yield the best results.

Tip 4 Optimize the Bed Temperature

Bed temperature plays a significant role in print adhesion, and thus, leveling. Different filaments require different bed temperatures. For example, PLA typically prints well with a bed temperature of 60°C, while ABS requires higher temperatures, usually around 110°C. Proper bed temperature helps the first layer stick to the bed and prevents warping during printing. The heated bed warms the plastic, helping it adhere and expand without curling. A bed that is too cold can cause the first layer to peel off. A bed that is too hot can cause the first layer to deform. The image optimal-bed-temperature.webp helps to understanding this. Always consult the filament manufacturer’s recommendations for the ideal bed temperature.

How Bed Temperature Affects Adhesion

The bed temperature affects adhesion by influencing how the filament cools and contracts. When the filament is deposited on the bed, it should cool slowly and evenly. If the bed is at the correct temperature, the filament will bond to the bed, and cooling will proceed at the correct rate to reduce warping and increase adhesion. If the bed is too cold, the filament will cool too quickly and might not stick to the bed. If it’s too hot, the filament might become too soft, leading to oozing or warping. Experiment with the bed temperature to find the optimal setting for the filament and the environment. Using a brim or raft can also help improve adhesion, especially for prints with a small footprint.

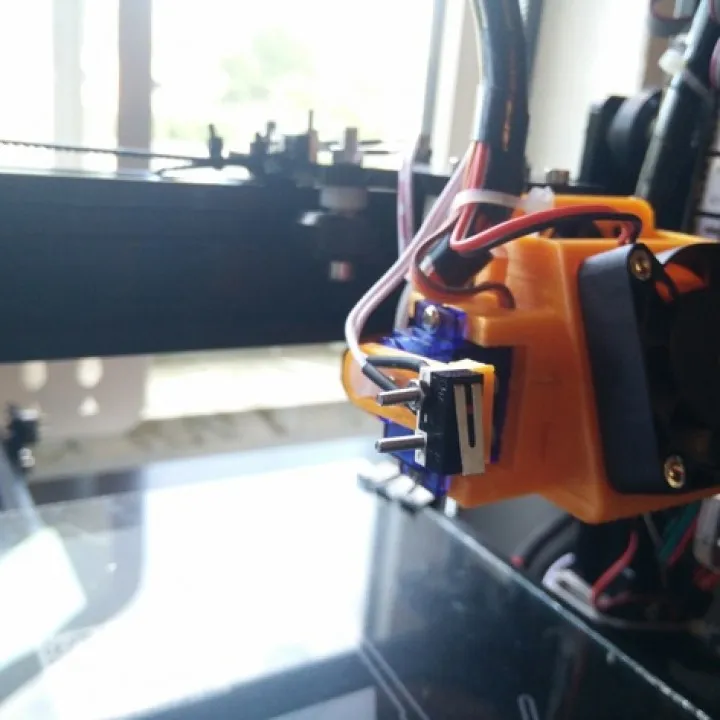

Tip 5 Fine-Tune With a Leveling Probe

A leveling probe, if your Tevo Tarantula is equipped with one, automates the bed leveling process. The probe measures the distance between the nozzle and the bed at multiple points, creating a mesh of the bed’s surface. The printer then uses this information to compensate for any unevenness. It’s important to calibrate the probe correctly to ensure accurate measurements. The probe is an advanced solution to compensate for imperfections in the print bed. With a probe, you can achieve much more precise leveling and improve the first layer of your prints, even if the bed is not perfectly flat. The image leveling-probe-calibration.webp represents this.

How to Calibrate a Leveling Probe

To calibrate a leveling probe, follow the manufacturer’s instructions for your specific probe model. Typically, you will need to set the Z-offset, which is the distance between the probe’s trigger point and the nozzle. This is crucial for accurate measurements. You will also calibrate the probe by running the leveling procedure, which measures the bed’s surface. During calibration, the printer moves the nozzle to different points on the bed, taking measurements. Ensure the bed is clean and that the printer is on a stable surface. Perform a few test prints to fine-tune the Z-offset. After each calibration, test the print to see if it improves. Adjust the settings until the first layer adheres consistently. Remember that regular calibration is essential for optimal performance.

Troubleshooting Tevo Tarantula Bed Leveling Issues

Common Leveling Issues and Solutions

If you encounter leveling problems, consider these common issues and solutions. If the nozzle is too far from the bed, the filament will not adhere, and the print will not stick. Lower the bed or raise the Z-axis endstop. If the nozzle is too close, the filament will be squished, possibly causing a clogged nozzle or elephant’s foot. Raise the bed or lower the Z-axis endstop. Warping can occur if the bed temperature is incorrect or if the bed is not leveled evenly; adjust the bed temperature and re-level the bed. Inconsistent layer lines may indicate uneven leveling or a warped bed; carefully check your leveling process. Be patient, and don’t hesitate to repeat the steps or consult online resources for your printer.

Preventative Maintenance for Consistent Leveling

Regular maintenance ensures consistent bed leveling and optimal 3D printing performance. Clean your print bed frequently. Use a glass cleaner or isopropyl alcohol to remove any residue or fingerprints. Check the bed for warps or damage. Over time, the bed can warp due to heat or wear and tear. Inspect the bed surface for any imperfections and replace it if necessary. Regularly check the tightness of the bed leveling knobs and the Z-axis endstop. If the components become loose, the bed level may change. Regularly clean the nozzle and print bed. The image tevo-tarantula-leveling-maintenance.webp display this process. Following these steps will keep your printer printing and leveled with good results.

Conclusion Leveling Your Tevo Tarantula

Mastering bed leveling on your Tevo Tarantula is essential for 3D printing success. The provided tips and techniques help you achieve the perfect first layer and improve your print quality. Remember to adjust the Z-axis endstop, use the paper test, adjust bed leveling knobs, and optimize bed temperature. If available, use and calibrate a leveling probe. Troubleshooting and preventative maintenance, such as cleaning the bed and checking for warps, are important parts of the process. By following these tips and practicing, you can become proficient in leveling your printer and enjoy successful 3D printing projects. Happy printing.