The Tarantula Prusa i3, a popular entry-level 3D printer, has gained significant traction among hobbyists and newcomers to the 3D printing world. This review delves into the top five features that make the Tarantula Prusa i3 a compelling choice, examining its performance, ease of use, and overall value. From print quality to assembly, we’ll explore what this machine brings to the table, helping you determine if it’s the right 3D printer for your needs. We’ll analyze its strengths and weaknesses, providing a comprehensive overview to guide your decision-making process and making sure you get the best 3D printing experience.

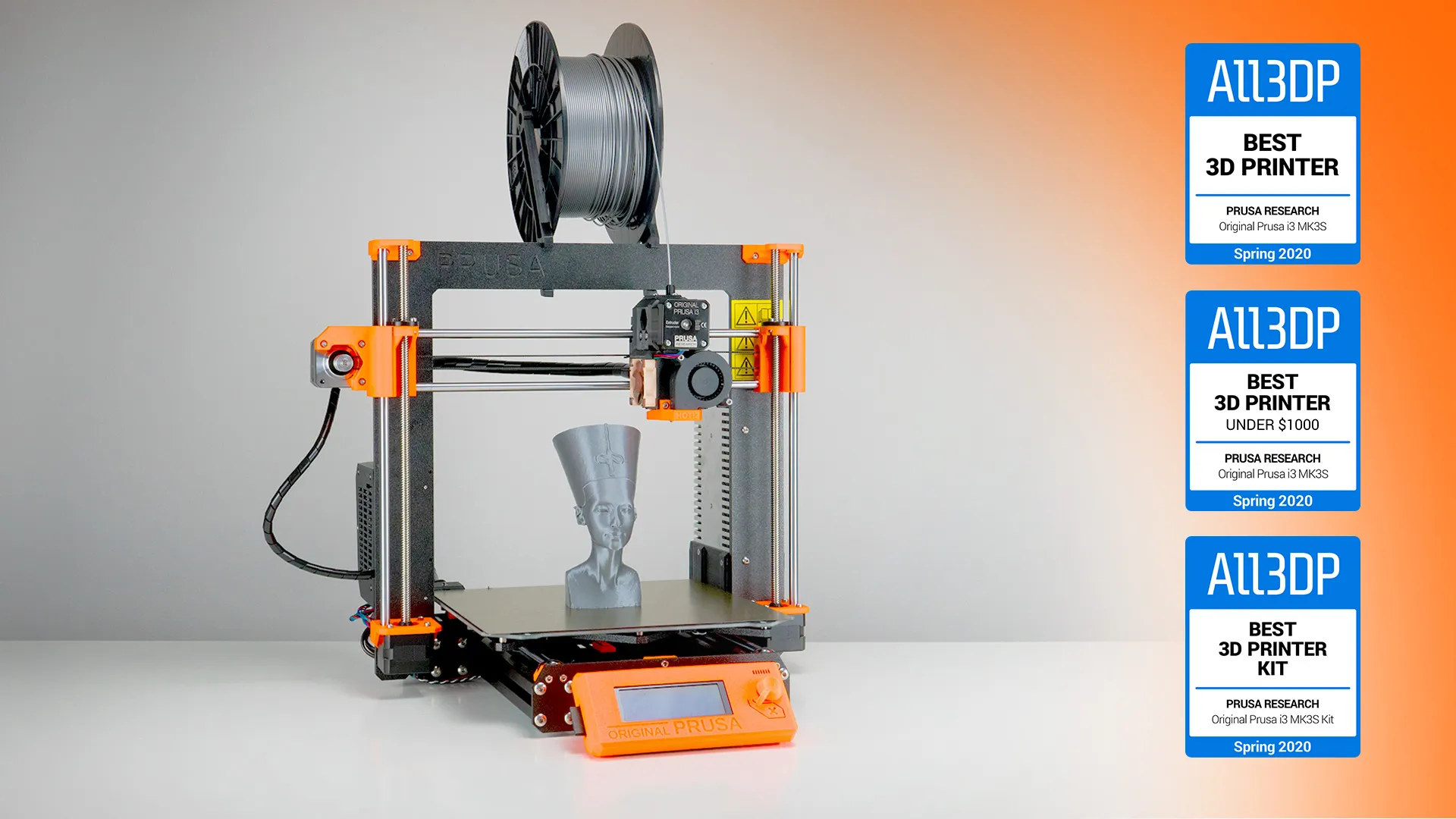

Print Quality

Print quality is a critical aspect of any 3D printer, and the Tarantula Prusa i3 offers a respectable performance in this regard. It excels in producing functional parts and prototypes. While it may not achieve the same level of detail as more expensive printers, the Tarantula Prusa i3 delivers satisfactory results for its price range. The ability to create functional objects quickly and efficiently makes it an excellent tool for prototyping and small-scale manufacturing. The printer’s print quality is a balance of cost-effectiveness and functionality, making it a good starting point for beginners learning about 3D printing.

Layer Adhesion

Layer adhesion is crucial for the structural integrity of 3D-printed objects, and the Tarantula Prusa i3 generally performs well in this area. Properly calibrated and maintained, the printer can produce parts with strong layer bonding, which is essential for creating durable and reliable prints. Proper settings and careful attention to the printing environment significantly impact layer adhesion. This ensures that the layers of filament fuse together seamlessly, creating robust and dependable models. The machine allows for adjustments to printing parameters, enabling users to optimize layer adhesion based on the filament and desired object characteristics.

Fine Details

The ability to reproduce fine details is a key indicator of a 3D printer’s precision. While the Tarantula Prusa i3 might not match the resolution of high-end printers, it can still handle reasonably intricate designs. It is capable of printing small features and detailed geometries, albeit with some limitations. The precision of the Tarantula Prusa i3 makes it suitable for a range of applications, including creating detailed prototypes, custom components, and educational projects. The user’s ability to make minor adjustments for optimal print results is essential for achieving satisfactory outcomes. This provides a great starting point for those exploring 3D printing and experimenting with designs.

Print Speed

Print speed is a key consideration, especially when rapid prototyping or creating multiple parts. The Tarantula Prusa i3 offers a decent print speed, allowing users to produce objects within a reasonable timeframe. The speed is optimized with the quality of the output object, and this allows for balance. Print speed greatly affects how quickly you can turn your designs into physical objects. Various adjustments can improve your printing results. Balancing the desired print speed with the quality requirements is a crucial step for users. This feature contributes to the printer’s appeal for both enthusiasts and professionals.

Assembly & Setup

The assembly and setup process is a critical step for any 3D printer. The Tarantula Prusa i3 is known for its relatively straightforward assembly process, making it accessible to beginners. The kit comes with detailed instructions, guiding users through each step of the build process. Though some assembly is required, this process provides a valuable learning opportunity about the printer’s components and functionality. The hands-on approach makes it easier to understand and maintain the machine, and it is a benefit for those new to 3D printing. With patience and attention to detail, users can successfully assemble and begin printing with their Tarantula Prusa i3.

Ease of Assembly

The Tarantula Prusa i3’s ease of assembly is a significant advantage for newcomers to 3D printing. The kit’s design and instructions are carefully designed to simplify the build process. The printer’s modular components and clear instructions reduce the complexity, making it less intimidating for those without prior experience. Even those new to this will get a better experience with this machine. This feature allows users to start using the printer quickly and comfortably. With careful attention to the instructions and a bit of patience, users can successfully assemble and start printing with their Tarantula Prusa i3.

Calibration Process

Calibration is essential for achieving good print quality. The Tarantula Prusa i3 includes a basic calibration process to ensure the print bed is level and the nozzle height is correct. Proper calibration can be achieved through manual adjustments and careful settings adjustments. Regular calibration checks are a must and ensure the printer produces the quality prints it is meant to. Understanding and mastering the calibration process is fundamental for ensuring successful 3D printing outcomes.

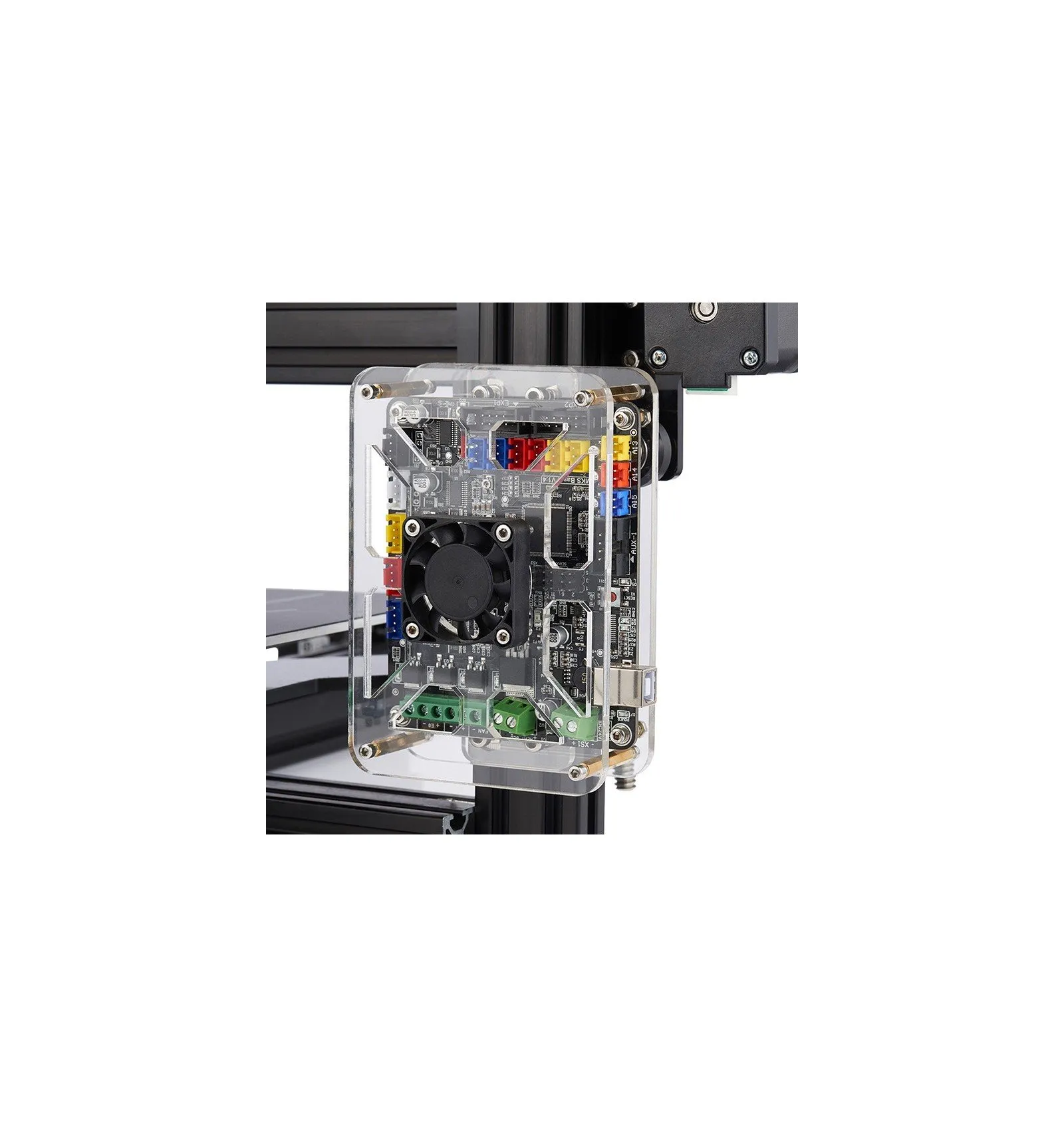

Extruder & Hotend

The extruder and hotend are critical components that determine the printer’s ability to melt and deposit filament accurately. The Tarantula Prusa i3 features a standard extruder design, which can handle a variety of filaments. The hotend heats the filament to its melting point, allowing it to be extruded onto the build plate. The performance of these parts directly impacts print quality and the types of materials that can be used. Regular maintenance and cleaning of the extruder and hotend are essential for smooth and consistent printing. The extruder and hotend are responsible for filament feeding and melting, which is vital for reliable operation.

Nozzle Performance

The nozzle plays a critical role in determining the level of detail and precision in 3D prints. The Tarantula Prusa i3’s nozzle generally performs well for entry-level printers, allowing for good results. The nozzle size influences the printing quality, with smaller nozzles enabling finer details. Users can experiment with various nozzle sizes to optimize print results, and the nozzle’s condition is vital for consistent printing. Regular maintenance, including cleaning and replacement, is essential for maintaining the nozzle’s performance. The nozzle is responsible for extruding the melted filament, and its condition greatly affects the overall print quality.

Filament Compatibility

Filament compatibility is a key factor in determining the range of materials you can use with the Tarantula Prusa i3. The printer is compatible with commonly used filaments, such as PLA and ABS, which are suitable for a wide variety of projects. Users can experiment with various filament types to discover different properties and features. Understanding the characteristics of different filaments is essential for achieving the desired print results. The ability to use various filament options enhances the versatility of the Tarantula Prusa i3, making it suitable for many applications.

Build Volume

Build volume refers to the maximum size of the objects that can be printed. The Tarantula Prusa i3 offers a build volume suitable for small to medium-sized prints. This is a good starting point for hobbyists and those new to 3D printing. Users can take advantage of their prints to create useful and functional prototypes or projects. Build volume helps to decide which objects can be produced with a 3D printer. The size of the printer is suitable for numerous applications, including prototypes and small projects.

Dimensions

The dimensions of the printer contribute to its suitability for different workspaces. The Tarantula Prusa i3 has a relatively compact footprint, making it suitable for home use or smaller workspaces. Its dimensions allow for easy placement on a desk or table. The compact design makes it portable and easy to manage. The size and dimensions of the printer are key factors in its practical use and convenience.

Usable Print Area

The usable print area defines the maximum space available for printing objects. The Tarantula Prusa i3 has a print area that fits small to medium-sized objects. The area allows for the creation of useful and functional items for a range of projects. The usable print area is a key factor in determining the scale of the objects that can be printed. Being aware of the print area helps in deciding the models that can be printed on the machine. The usable print area is a significant consideration for users looking to print parts or prototypes.

Software & Firmware

The software and firmware play a crucial role in controlling and optimizing the 3D printing process. The Tarantula Prusa i3 typically uses open-source software and firmware, providing users with flexibility and customization options. This open-source approach encourages experimentation and allows for easy modifications. Users have access to the settings which will make their 3D printing experience. Proper management of software and firmware is essential for achieving the best print results and the printer’s overall functionality.

Firmware Updates

Firmware updates can improve the performance and add new features to the Tarantula Prusa i3. Regular firmware updates often include improvements to printing quality, bug fixes, and new features. Users should install firmware updates to make sure the printer is optimized and working correctly. Firmware updates enhance the printer’s capabilities, and users should stay updated on any releases. Keeping your firmware up to date is crucial for a better 3D printing experience.

Slicer Software

Slicer software is essential for converting 3D models into instructions that the printer can understand. The Tarantula Prusa i3 is compatible with various slicer programs, such as Cura and Simplify3D. Slicer software allows users to configure settings like layer height, print speed, and support structures. The choice of slicer software can significantly impact the print quality and ease of use. Familiarity with slicer software is essential for any user. Understanding slicer software settings is crucial for maximizing the printing quality of the Tarantula Prusa i3.

In conclusion, the Tarantula Prusa i3 offers a compelling package with its focus on print quality, ease of use, and affordability. While there may be certain trade-offs in print resolution and advanced features compared to more expensive models, its top five features, including print quality, easy assembly, and a versatile filament selection, make it an excellent choice for both beginners and hobbyists looking to explore the world of 3D printing. Its solid performance and overall value make the Tarantula Prusa i3 a worthwhile investment for those starting their 3D printing journey.