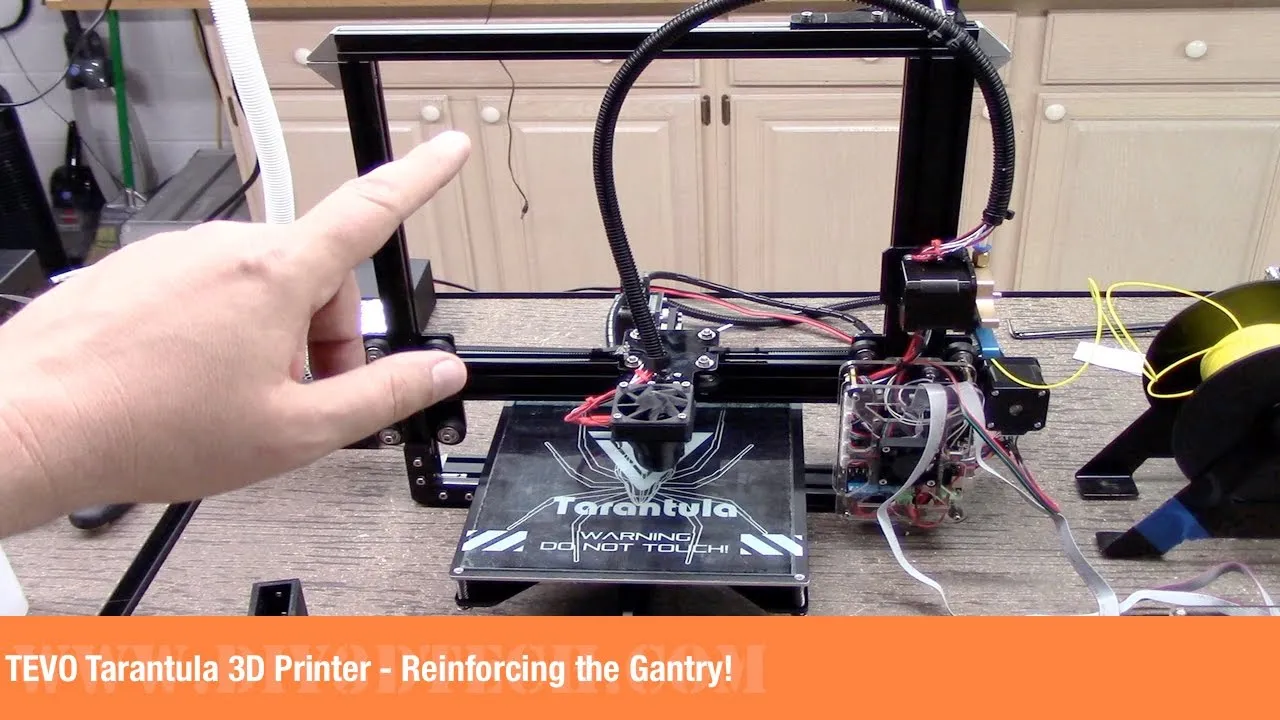

What is Tarantula 3D Printer Software

Tarantula 3D printer software is the crucial link between your 3D printer and the digital models you want to create. It encompasses a range of applications, from slicers that convert digital designs into printer-readable instructions to post-processing tools that refine the final product. The right software is essential for a successful 3D printing experience. Without it, your Tarantula 3D printer is just a collection of components. Understanding the different software types and their functions is the first step toward unlocking the full potential of your machine. This includes not only slicing software but also firmware updates and control interfaces, all of which contribute to the overall print quality and user experience.

Understanding the Basics

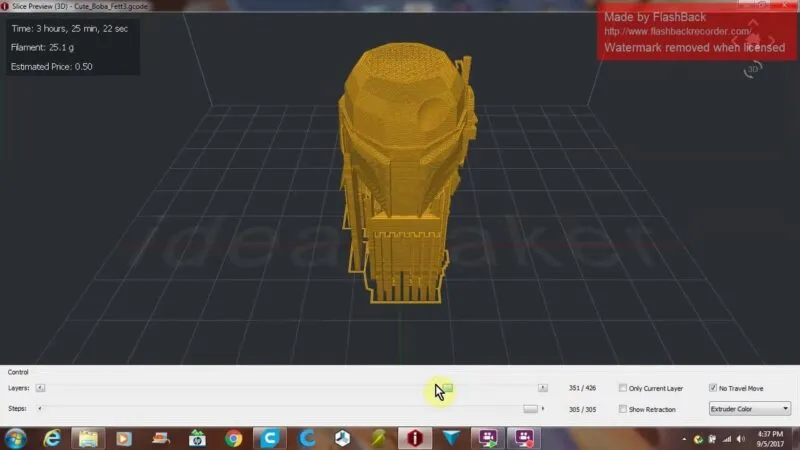

At its core, Tarantula 3D printer software facilitates the transformation of digital 3D models (typically in STL or OBJ format) into physical objects. This process involves several key steps. First, the software slices the 3D model into thin layers. Then, it generates G-code, a programming language that instructs the printer’s motors, extruder, and bed on how to move and deposit material layer by layer. This software also controls the printer’s settings, such as temperature, print speed, and layer height. Many software solutions offer a user-friendly interface and customization options to meet the needs of both beginners and advanced users. Careful selection and proper configuration of these settings significantly influence print quality, speed, and material use.

Why is Software Important?

The software’s impact on print quality, ease of use, and the types of projects that can be undertaken is substantial. It determines how accurately your printer can translate your digital designs into physical objects, influencing details, surface finish, and structural integrity. A well-chosen software suite can also significantly streamline the printing process, offering features like automatic supports, model repair, and remote monitoring. Software updates are frequently released to address bugs, add new features, and improve performance. Neglecting software can lead to print failures, poor print quality, and limit the capabilities of your Tarantula 3D printer, thus making it essential to invest time in learning and utilizing effective software solutions.

Top 5 Secrets for Tarantula 3D Printing Software

Secret 1 Optimize Slicer Settings

Slicer settings directly affect the quality of your 3D prints. Experimenting with different settings is crucial for achieving optimal results. This includes layer height, infill density, print speed, and temperature. These adjustments fine-tune how your printer deposits material, impacting details, strength, and print time. Carefully selecting these parameters ensures that you get the best possible output from your Tarantula 3D printer. Different materials also have different setting requirements, therefore understanding how these settings interact is fundamental to high-quality 3D printing. Regularly review and modify your slicer profiles based on the models you’re printing and the materials you’re using.

Choosing the Right Slicer

Selecting the correct slicer can significantly improve your printing results. Popular options like Cura, PrusaSlicer, and Simplify3D offer various features and capabilities. Choosing the right one depends on your needs and experience level. Cura, for instance, is known for its user-friendly interface and wide range of customization options, making it excellent for beginners. PrusaSlicer is optimized for Prusa printers but works well with others and offers advanced features like multi-material printing. Simplify3D is a paid option that provides enhanced control and a highly detailed preview of the printing process. Each slicer provides a unique set of capabilities and profiles, enabling you to select the tool that best fits your printing requirements.

Fine-tuning Print Speed and Temperature

Print speed and temperature are critical for the quality and precision of your prints. If the speed is too fast, the printer might struggle to deposit the material smoothly, causing imperfections or layer separation. If the temperature is too low, the filament won’t melt properly, leading to weak bonds between layers. Adjustments should be made depending on the filament type and model complexity. For example, PLA requires lower temperatures and slower speeds than ABS. Finding the optimal settings involves experimentation and understanding the filament’s characteristics. Always start with the manufacturer’s recommended settings and then fine-tune the parameters according to your specific printing needs and the performance of your Tarantula 3D printer.

Secret 2 Master Bed Adhesion Techniques

Bed adhesion ensures that your prints stick to the print bed throughout the entire printing process. Effective bed adhesion prevents warping, where the edges of the print lift off the bed, and also ensures proper layer adhesion. Without good adhesion, the prints will separate from the bed, resulting in failed prints. Several methods can improve bed adhesion, including using specialized bed surfaces, applying adhesives, and calibrating the bed. When the bed is level and clean, it improves the chances of a successful print. Proper adhesion is particularly important for larger or more complex prints. Proper bed adhesion techniques are crucial for reliable and high-quality 3D printing results.

Using Glue Stick and Other Adhesives

Applying adhesives can be a simple, effective way to improve bed adhesion. Glue stick, specifically designed for 3D printing, provides a barrier between the print and the bed surface, preventing warping. Other effective adhesives include hairspray and blue painter’s tape. The choice of adhesive depends on the filament being used. For example, ABS prints often benefit from a glue stick. When using adhesives, ensure an even application across the entire print bed. After printing, remove the print and clean the bed to prepare for the next print. Properly applied adhesives increase the chance of successful prints and reduces the likelihood of print failures. It’s best to apply a thin, even layer of the chosen adhesive to the bed surface.

Leveling the Print Bed

A level print bed is essential for consistent and reliable prints. If the bed is not level, the first layer will not adhere properly. This can cause the print to detach from the bed during printing. Many Tarantula 3D printers have manual or auto-leveling systems. Manual leveling requires you to adjust the bed height using screws. Auto-leveling uses sensors to measure the bed’s surface and adjust the print head’s position accordingly. Before each print, level your bed. Even small adjustments can make a significant difference in print quality. A properly leveled bed ensures that the first layer of filament adheres evenly, which in turn sets the foundation for the rest of the print. Consistent bed leveling is a critical step.

Secret 3 Calibrate Your Extruder

Calibrating your extruder ensures that the correct amount of filament is pushed through the nozzle during printing. The calibration process ensures that the printer extrudes the correct amount of filament for a given command. Without calibration, the printer might under-extrude (not enough filament) or over-extrude (too much filament). Under-extrusion can cause weak layers or gaps in the print. Over-extrusion can cause the print to bulge and warp, reducing the accuracy. Accurate calibration leads to stronger, more detailed prints. It also reduces the likelihood of print failures. The steps involved are critical for achieving consistent and high-quality 3D prints with your Tarantula 3D printer.

Steps to Calibrate the Extruder

Extruder calibration involves measuring the amount of filament the extruder pushes through the nozzle. First, heat the nozzle to the temperature recommended for your filament type. Then, mark the filament a certain distance from the extruder. Next, command the extruder to push a specific length of filament, usually 100mm. Then, measure the distance between the mark and the extruder. If the measurement is off, adjust the E-steps setting in your printer’s firmware. This setting controls the number of steps the extruder motor makes for each millimeter of filament extruded. After each adjustment, repeat the calibration process to ensure accuracy. Correct extruder calibration is a critical process for achieving the best prints.

Troubleshooting Extrusion Issues

Troubleshooting extrusion problems can be a time-consuming process, but necessary for achieving high-quality prints. If you notice under-extrusion, check for clogs in the nozzle, and adjust the extruder’s temperature. Check the nozzle temperature, filament path, and extruder gear for issues. Over-extrusion might result from incorrect E-step settings or a blocked nozzle. Regular maintenance, such as cleaning the nozzle and checking for loose connections, can prevent extrusion problems. By learning how to identify and fix common issues, you can significantly improve your printing results. Remember that troubleshooting is an iterative process; testing and refining your settings is key to ensuring your printer’s best possible performance.

Secret 4 Embrace Post-Processing Software

Post-processing software enhances the final appearance of your 3D prints. These tools allow you to address imperfections, add finishing touches, and refine the details of your print. While the printer software shapes the object, post-processing tools make it look refined. These tools can correct minor defects, such as layer lines or support marks, and also enable more advanced modifications. These software packages can also improve the surface finish of 3D prints. Investing time in post-processing can elevate your prints from functional prototypes to attractive, finished products. Experiment with different tools to refine your prints and make them visually appealing.

Examples of Post-Processing Tools

Many types of post-processing software packages are designed to refine 3D prints. MeshMixer, for example, is free software that is ideal for repairing models, smoothing surfaces, and adding supports. Netfabb is another popular tool that can repair models and analyze them for printability. Software can also be used to add textures, colors, and other visual effects. Consider tools like Blender for more advanced operations like texturing and rendering. The right software can help you quickly make changes to your models and refine the final product. These tools offer a wide range of capabilities, letting you transform your 3D prints from prototypes to finished items.

Improving Print Aesthetics

The appearance of your 3D prints can be improved with post-processing tools. Some key steps include sanding surfaces to remove layer lines, applying fillers to smooth imperfections, and painting or coating the prints to change their appearance. Using these tools can help you create professional-looking prints. For example, sanding can smooth rough surfaces, making them look much cleaner. Fillers like epoxy resin can fill in gaps and imperfections. A well-applied finish can enhance the visual appeal and durability of your prints. Combining these techniques with the appropriate software tools will produce high-quality, visually appealing 3D prints. Remember that patience and attention to detail are key to achieving professional-looking results.

Secret 5 Keep Software Updated

Regular updates ensure that your 3D printing software operates at its best. Software updates provide bug fixes, new features, and improvements to performance. Keeping your software current can prevent printing errors and ensure that you can use the latest features. Updates often include improvements to the user interface, slicing algorithms, and support generation. By updating your software, you can often improve print quality and reliability. Regularly updating the firmware on your printer also ensures optimal performance, which is one of the simplest ways to improve your printing experience. Regularly check for updates to your slicer and firmware to keep your printer running smoothly.

Why Updates Matter

Software updates address bugs, add new features, and improve overall performance. Updates often include fixes for common printing problems, enhanced support for different materials, and improved slicing algorithms. They are released frequently by the software developers. They can make the software more user-friendly. They also increase the performance of your Tarantula 3D printer. By updating your software, you can access these enhancements and ensure that your printer works efficiently. Software updates can dramatically improve print quality, provide a more efficient workflow, and keep your printing experience up-to-date with the latest technology.

How to Update Software

Updating your 3D printing software is usually straightforward. Most slicers have an automatic update feature. Check for updates in the software’s settings or through the software itself. Firmware updates are usually done by connecting the printer to a computer and installing the update through the printer’s control panel. Before updating, always back up your existing settings to avoid losing your custom profiles. Software manufacturers often provide detailed instructions on how to perform the updates. Following these steps will ensure that your printer operates with the latest features and enhancements.

Conclusion

Mastering the software for your Tarantula 3D printer involves understanding the key components and utilizing the best practices. By optimizing slicer settings, mastering bed adhesion, calibrating the extruder, using post-processing tools, and keeping your software updated, you can dramatically improve your printing results. These five secrets provide a solid foundation for achieving consistent, high-quality prints. By incorporating these strategies into your workflow, you can unlock the full potential of your Tarantula 3D printer and transform your digital designs into reality. Embrace the learning process, experiment with different techniques, and enjoy the exciting world of 3D printing. With practice and patience, you’ll be able to create amazing prints.