Top 5 Tevo Tarantula Upgrades in Montreal

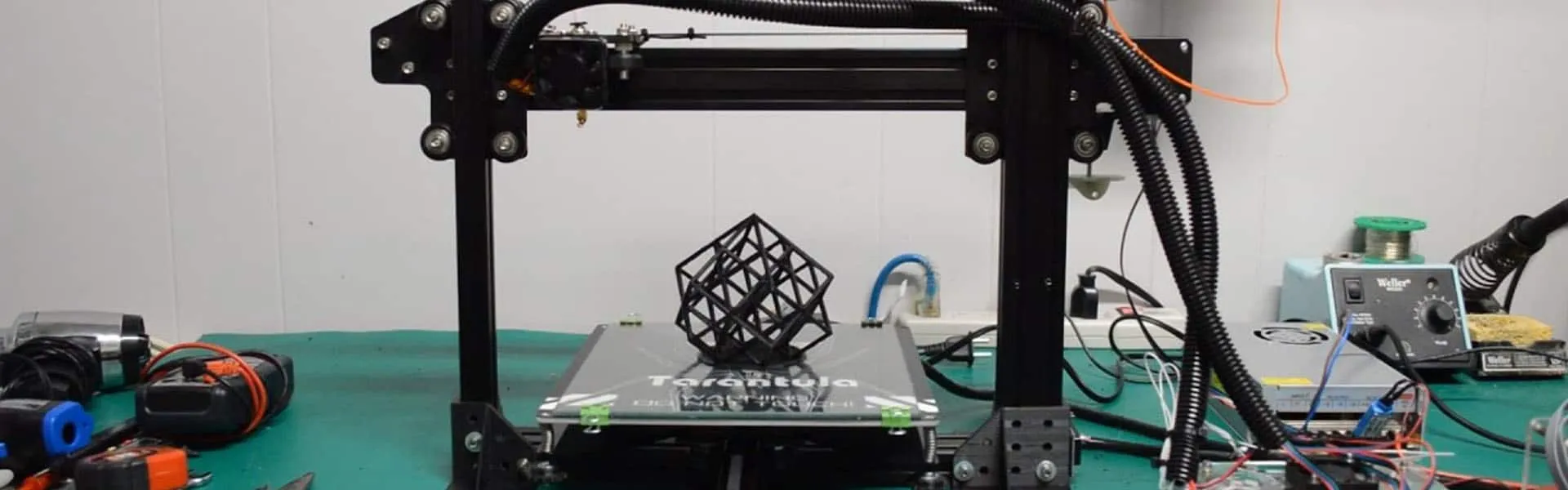

The Tevo Tarantula is a popular 3D printer, known for its affordability and ease of use. However, like any entry-level machine, there’s always room for improvement. For 3D printing enthusiasts in Montreal, upgrading your Tevo Tarantula can significantly enhance print quality, reliability, and overall user experience. This guide explores five essential upgrades to take your 3D printing projects to the next level. From optimizing the extruder to fine-tuning your software, these modifications will help you achieve smoother prints, reduce common issues, and explore new materials. Whether you’re a beginner or an experienced maker, these upgrades are accessible and will greatly improve your printing experience.

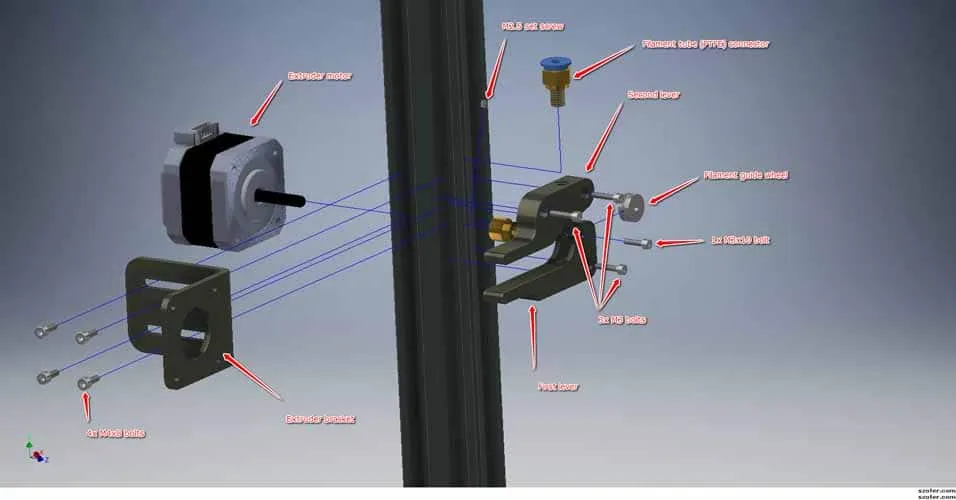

Extruder Upgrades for Enhanced Printing

The extruder is responsible for pushing filament through the hotend, and a reliable extruder is crucial for consistent prints. Upgrading the extruder can eliminate common problems like under-extrusion or filament jams. Consider these upgrades to improve this vital part of your printer, ensuring a smoother and more accurate printing process. A well-performing extruder directly translates into better layer adhesion and overall print quality, providing greater satisfaction in your Montreal 3D printing endeavors.

Upgrading the Extruder Motor

A stronger or more precise extruder motor can improve filament feeding. The stock motor might be adequate for basic printing, but upgrading to a higher-torque stepper motor can provide more consistent extrusion, especially with demanding filaments. This upgrade is relatively inexpensive and easy to install, yet it can noticeably improve print quality and reduce issues like under-extrusion. Ensure the new motor’s specifications match the existing driver on your control board or make the necessary driver adjustments, providing optimal power for the filament feed, resulting in a noticeable improvement in the final print quality.

Hotend Improvements for Better Prints

The hotend is where the filament melts, and optimizing it is key to achieving excellent prints. Switching to an all-metal hotend can allow for higher printing temperatures, expanding your material options. The stock hotend on the Tevo Tarantula might have limitations with certain filaments. Additionally, upgrading the heat block or adding a silicone sock can improve heat distribution and reduce temperature fluctuations, leading to more consistent extrusion and better print quality. Proper thermal management of the hotend makes the Montreal 3D printing experience more efficient, reliable, and adaptable to various filaments.

Bed Leveling Solutions for Perfect Adhesion

Bed leveling is critical for the first layer adhesion, which is the foundation of every successful print. Many users struggle with this, but fortunately, there are several effective solutions. Accurate bed leveling ensures the first layer adheres properly to the bed, which is critical for the print’s structural integrity and overall success. Implementing these techniques will eliminate common frustrations associated with bed adhesion and improve the printing experience in Montreal.

Manual Bed Leveling Techniques

Manual bed leveling involves adjusting the bed height using the leveling screws at each corner. This requires patience and precision, but mastering it is essential for any 3D printer user. Using a piece of paper to gauge the distance between the nozzle and the bed is a common method. Practice and patience are key. Ensure that the nozzle is the correct distance from the bed to achieve a good first layer. Regularly checking and adjusting the bed level is an important part of maintaining the printer and ensuring consistent print quality. This skill is invaluable for the Montreal 3D printing community.

Automatic Bed Leveling with a Sensor

Automatic bed leveling (ABL) uses a sensor to measure the bed’s surface and automatically adjust the nozzle height during printing. This upgrade greatly simplifies the leveling process and can compensate for minor bed imperfections. Popular sensors include inductive, capacitive, and BLTouch. Installing an ABL sensor can dramatically reduce the time and effort spent on leveling, providing more accurate first layers, and saving you from failed prints. This is a highly recommended upgrade for users looking to streamline their 3D printing workflow in Montreal.

Electronics and Firmware Upgrades

Upgrading the electronics and firmware can significantly improve the Tevo Tarantula’s performance and capabilities. Modernizing the control board allows for better processing power and the ability to use advanced features. This step can open up more possibilities, from improved print quality to enabling new features like auto bed leveling. Properly managing the electronics and firmware is a crucial step in improving the Tevo Tarantula’s capabilities.

Choosing a New Control Board

The stock control board may be limited in terms of features and processing power. Upgrading to a more advanced board, such as an Arduino-based board with a dedicated 32-bit processor or a board with TMC drivers, can bring many benefits. Features like silent stepper motor drivers, which reduce noise, and expanded memory for more complex firmware are all part of the experience. When selecting a new board, ensure that it’s compatible with your existing components and consider features that align with your printing needs. Many Montreal 3D printing enthusiasts find this a worthwhile upgrade.

Firmware Updates and Customization

Updating the firmware is crucial for optimizing your printer’s performance and enabling new features. Marlin firmware is a popular choice, offering extensive customization options and support for various upgrades. Customizing the firmware allows you to fine-tune settings like acceleration, jerk, and steps per millimeter for optimal printing. Regularly updating your firmware and exploring the customization options available can greatly improve your print quality and user experience. This ensures the printer runs smoothly, consistently, and addresses any issues, such as those that plague the Montreal 3D printing community.

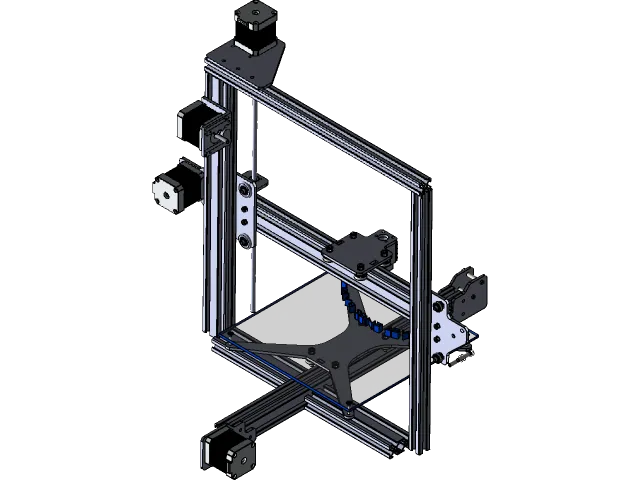

Structural Enhancements for Stability

The Tevo Tarantula’s frame can benefit from structural enhancements to improve stability and reduce vibrations. This can lead to higher print quality, especially at faster speeds. Reinforcing the frame makes the printer more rigid, reducing wobbling and inconsistencies that can show up in prints. By focusing on structural improvements, users can improve the overall reliability and accuracy of their prints. For users in Montreal, stability upgrades are a practical step toward achieving better results, no matter the project.

Reinforcing the Frame

Adding braces and supports to the frame can significantly improve its rigidity. Common modifications include adding corner brackets, reinforcing the Z-axis supports, or using a stronger frame material. These improvements reduce flex, especially during fast movements, which translates into sharper and more precise prints. The resulting print quality and reliability improvements make it a worthwhile upgrade for any Tevo Tarantula owner in Montreal.

Adding Braces and Supports

Adding braces and supports, especially to the Z-axis, enhances stability and minimizes vibrations. This can improve print accuracy and reduce artifacts. Popular methods include 3D printing or purchasing brackets designed for the Tevo Tarantula. The addition of these elements stiffens the frame and promotes smoother operation, leading to more consistent and higher-quality prints. These simple additions can make a world of difference in the quality of your prints.

Software and Slicing Optimizations

Optimizing your slicer settings and filament profiles is crucial for achieving excellent print quality. Even with hardware upgrades, the software plays a significant role in the final outcome. Fine-tuning your slicer settings and filament profiles ensures that your hardware upgrades are fully utilized. Taking the time to optimize settings can lead to improved print quality, reduced waste, and the ability to work with a broader range of materials.

Selecting the Right Slicer Settings

The slicer converts 3D models into instructions that the printer can understand. Choosing the right slicer settings is key to achieving the best prints. Parameters like layer height, infill density, print speed, and temperature all affect the final quality and strength of the printed object. Experimenting with different settings and testing different filaments is the best way to find the optimal configuration for your printer and materials. Consider that adjusting print speeds, layer heights, and temperatures will all affect the final output.

Optimizing Filament Profiles

Each filament type requires different printing parameters to achieve optimal results. Create and fine-tune filament profiles in your slicer software to match the specific filament you are using. Key settings to adjust include printing temperature, bed temperature, and retraction settings. Start with the manufacturer’s recommendations and adjust from there based on your printer and environment. Properly optimized filament profiles will greatly improve print quality and consistency. This is crucial for the Montreal 3D printing community, as local conditions can affect printing results.

In conclusion, upgrading your Tevo Tarantula in Montreal is a rewarding endeavor. By implementing these five key upgrades - extruder enhancements, bed leveling solutions, electronics and firmware upgrades, structural improvements, and software/slicing optimizations - you can significantly enhance the performance of your printer. These improvements will lead to higher print quality, increased reliability, and a more enjoyable 3D printing experience. Embrace these upgrades and join the vibrant Montreal 3D printing community in creating amazing projects.